TeraCota 3500

Advanced non-contact measurement system for EV Battery production

TeraView presents a film thickness & density gauge designed for the battery industry.

The sensor can simultaneously determine both thickness and density for both cathodes and anodes in battery manufacturing. Conductivity can also be included, all in one sensor.

The terahertz sensor is non-contact and capable of delivering both point measurements in a laboratory application or ‘streaming’ data in a production environment.

Based on TeraView’s proprietary technology, the sensor represents a significant leap beyond the current method of measurement for quality and process control in the battery industry.

Production Features

• Works with both anode & cathodes.

• Non-contact, no marking or damage to coating material.

• High accuracy reporting of coating thickness, density & conductivity.

• Single-or-dual sided sensor options.

• Industrialised form factor; designed for battery manufacturing industry.

• Can be integrated with plant IT systems via network communications (ProfiNet, Ethernet/IP).

• Non-interpretive; automatic parameter calculation without operator input.

• Suitable for both laboratory or production deployment.

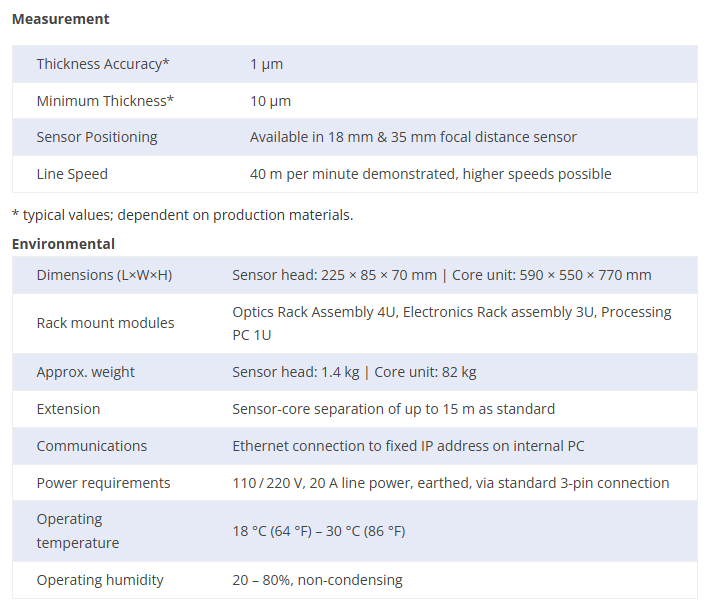

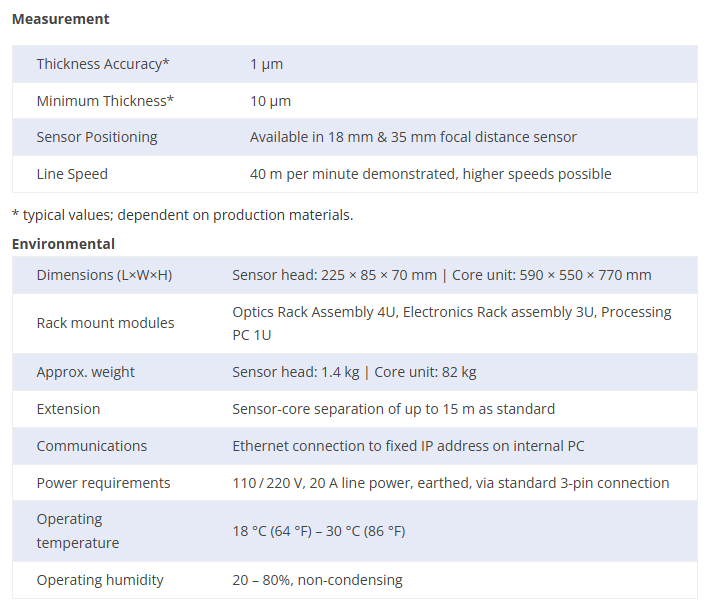

Technical Specification

The sensor can simultaneously determine both thickness and density for both cathodes and anodes in battery manufacturing. Conductivity can also be included, all in one sensor.

The terahertz sensor is non-contact and capable of delivering both point measurements in a laboratory application or ‘streaming’ data in a production environment.

Based on TeraView’s proprietary technology, the sensor represents a significant leap beyond the current method of measurement for quality and process control in the battery industry.

Technical Specification