Terahertz Applications

• Automotive Paints

• EV Battery

• Semiconductor Advanced Packaging Inspection

• Industrial Thin Films

• Analytical & Pharma

Coatings Inspection in Production

The wide range of imaging and spectroscopic capabilities offered by TeraView’s terahertz technology make it ideally suited for non-destructive evaluation, this enables inspection of layers in various materials that are challenging for other characterisation methods.

.png)

Coatings Inspection in Production - Details

EV Battery Production

Lithium-ion batteries are currently used to power most of the world’s portable electronic devices, such as smartphones, laptops, and tablets, and are increasingly used in hybrid and electric vehicles (EVs).

An important challenge in lithium-ion battery production is to optimize the manufacturing process for electrode coatings (cathode & anode) to improve and optimise capacity whilst reducing and controlling manufacturing costs. Key performance indicators that determine electrode performance include coating density, coating thickness and conductivity. To date, there is no sensor technology capable of simultaneously measuring all three of these quantities accurately and rapidly during the in-line coating process. Terahertz sensors offer a solution that provide density, thickness and conductivity in one measurement, allowing for real-time feedback and control.

Terahertz sensors have a successful track record in other in-line coating production applications. The coating density and thickness measured by Terahertz will dictate the capacity of the coatings used on the lithium-ion battery electrodes, and so will be the ultimate factors to optimise by changing the coating gap, line speed and other key parameters in coating production.

Terahertz thus offers the prospect of high performance electrode coatings delivered at lower costs and with the added insurance of secure supply to market.

EV Battery Production - Details

Semiconductor Packaging Inspection

Terahertz technology enables rapid high accuracy fault isolation in advanced semiconductor packages.

Advanced Packaging fault isolation case studies and advancement of Electro Optical Terahertz Pulse Reflectometry (EOTPR)

EOTPR is a well-established non-destructive fault isolation tool for advanced IC devices. These examples will show how EOTPR has been implemented to investigate a wide range of advanced package types, including 2.5D and 3D packages, wafer level fanout packages, and microelectromechanical (MEMs) devices. Further, we present the recent improvements to the EOTPR instrument and the results from a novel modelling approach that has the potential of vastly speeding up the fault localisation analysis.

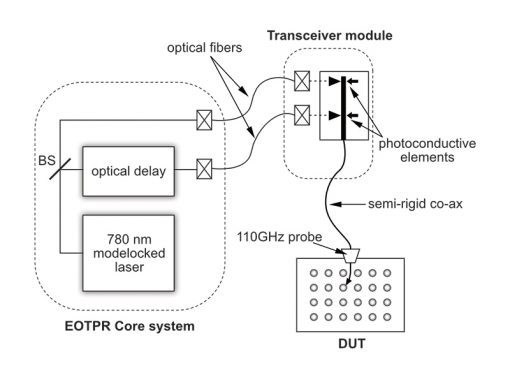

Electro-Optical Terahertz Pulse Reflectometry (EOTPR) is an implementation of the time domain reflectometry (TDR) technique at terahertz frequencies, proven to enhance fault isolation accuracy to better than 10 µm. As in conventional TDR, the fault detection accuracy of EOTPR is a function of the rise time of the incident pulse, the time-based jitter, and signal-to-noise ratio (SNR). The EOTPR instrument generates a terahertz pulse using an ultrafast laser and a pair of photoconductive switches for signal generation and detection, resulting in a system with (i) high measurement bandwidth, (ii) low time-base jitter, and (iii) a high time-base resolution.

Compared to conventional TDR, EOTPR generates signals with faster rise time, has greater SNR, and a much-reduced time base jitter; system properties that offer the potential for a significantly increased distance-to-defect accuracy.A schematic diagram of the EOTPR system is shown below.

Semiconductor Packaging Inspection - Details

Industrial Thin Films

TeraCota 3000 : A non-contact, single or multi-layer thickness sensor with scanning capability

TeraView presents a polymer film thickness gauge designed for industry.

The sensor can precisley determine thickness of single or multi-layer polymer films.

The terahertz sensor is non-contact and capable of delivering both ‘streaming’ data in a production environment and point measurements in the laboratory.

Based on TeraView’s proprietary technology, the sensor represents a significant leap beyond the current method of measurement for quality and process control in the polymer industry.

Industrial Thin Films - Details

Pharmaceutical

TeraView has successfully applied its proprietary terahertz imaging and spectroscopy technology to increase pharmaceutical product and process understanding as an effective part of the quality by design initiative.

Our systems utilise 3D terahertz pulsed imaging to nondestructively estimate critical quality attributes in pharmaceutical and medical products such as crystalline structure, thickness and chemical composition. TeraView Pharma Innovations team has demonstrated terahertz instruments produce 3D coating thickness maps for multiple coating layers and structural features models allowing better understanding and control of product scale up and manufacture.

Pharmaceutical - Details

Beyond 5G

TeraView is the pioneer and world leader in the development and commercialisation of terahertz technology, with applications with over 30 years’ unique experience operating at THz frequencies. TeraView has a vision to use its expertise and intellectual property to develop the building blocks of future 6G networks. To make this vision a reality, TeraView seeks partnerships with other companies and organizations with backgrounds in existing wireless communications markets. Since its inception, TeraView’s goal has been to make terahertz ubiquitous in everyday life.

Beyond 5G - Details

R&D Solutions : Terahertz Instrumentation for Research

Terahertz pulsed imaging provides an insight to disintegration failure in solid dosage form failure

Tablet disintegration is a property of products within the pharmaceutical industry that has been commonly investigated. The significance of disintegration lies in the availability of the active pharmaceutical ingredient (API) to be dissolved inside the body and reach the bloodstream to take effect. An up and coming approach for the analysis of tablet disintegration is terahertz pulsed imaging (TPI). TPI is a quick, efficient technique to perform these measurements.

R&D Solutions- Details

.png)